Case Studies

- Home

- Case Studies

Galloping to a $1B Company

Analyze. Implement small wins. Set high standards

How to Speed Output of New Products for Revenue Increase

The three levers for operations efficiency and profitability are people, process, and technology. The framework is based upon the balance of all 3 areas. Often, organizations will first develop a business case for heavy investment in technology to achieve greater operational efficiency. Instead of technology, focus on people and processes first to gain small wins in this situation. Are your PMO (Project Management Office) processes restricting the flow output of new products which is robbing your organization of potential sales? Is your budget for new investment limited?

Delays in key processes occur in the white space between the sender and receiver of deliverables. The gap is shortened when the silos are broken down and transparency of deliverable hand-offs between sender and receiver is increased

30% Nutrition revenue increase and 50 years high of Holiday revenue increase by implementing PMO efficiency programs with speed and execution excellence

A growing consumer goods company had a vision of a $1B organization. However, the siloed departments and the delays in new product launches hindered revenue growth. Key staff members would hold on their knowledge of the process for job security reasons.

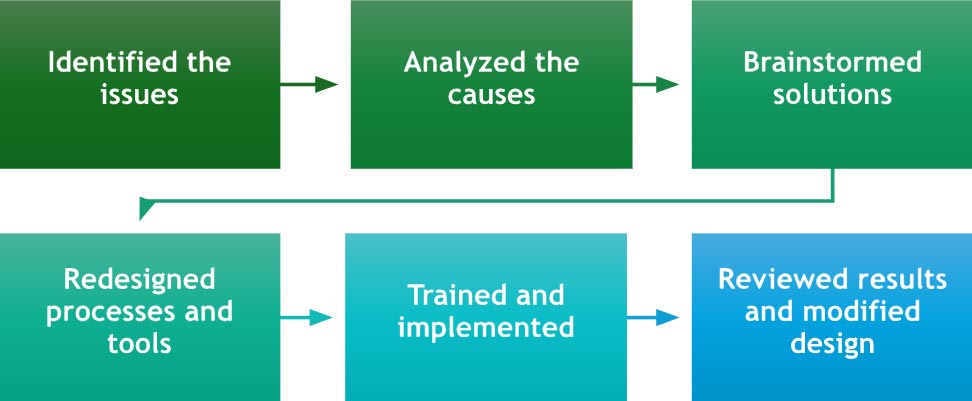

Organizational change management was brought in to address resistance and accountability. These delayed product launches depended upon the (NPI) or New Product Introduction process with stage gate approval. required extensive evaluation. faced this issue when business plans were not being achieved mainly due to sales performance not meeting projections. Retailers cited the lack of inventory to support ads as the primary reason. With insufficient inventory, the Retailer was stocking out which limited sales. Additionally, increased excess costs, increased shipping costs, impacted transition plans, and deteriorating relationships were also consequences. With detailed analyses, it was determined that the existing processes and information were ineffective in planning demand and supply in conjunction with Retailer’s needs. Brainstorming determined the best solution was a complete overhaul of the planning processes (sales forecasting, demand, supply), specifically adding weekly granularity and weekly frequency, to better align with Retailer planning. The redesign included:

- Development and modification of analysis and planning tools, including the master database

- Creation of a new schedule of weekly meetings and activities

- Cross-functional training

- Post-implementation review and process adjustments

As a result of the process redesign and implementation, unit sales increased 87% over the next two-year period. With better demand/supply alignment, there were fewer in-store stock outs, transitions improved, customer satisfaction increased, and the Manufacturer/Retailer relationship strengthened. Additionally, we recognized lower supply chain costs and mitigated excess and obsolete risk.